|

|

|

|

|

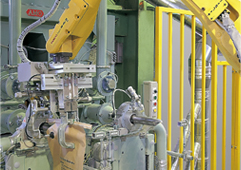

Realize unmanned Powder Packing Operation by the application of Industrial Robot System. |

|

|

Progressing a realization of Complete

Automatic Powder Packing System.

AMO ordinary type Bag Placer proves much worthy of our customer's

trust by realizing comfortable and efficient powder packing

environment using of variety of valve bag until now. However,

the said Bag Placcer can not be recovered and turned to operation

mode automatically when bag insertion into packer nozzle

incompletion has happened. In order to realize complete unmanned

Automatic Powder Packing System, AMO aims at industrial Robot

that recently shows remarkable technical progress, applies

that to Powder Packing Automation System and finally created

the ultimate unmanned Automatic Bag Placing System " RBT-BP-Series

'' after the long research and development span. |

|

|

Technical Features of the RBT-

BP Series |

Robotics

Bag Insertion System

Although manual operation can prevent bag insertion failure most effectively, AMO substitute Robot Bag Placing System for manual operation by applying its unique technical features. Thanks to pre-teaching procedures for the Robot motions, a variety of bag exchange becomes more easier. Also by changing Robot Hand parts, the Robot Bag Placer can be applied to a series of various bag configurations.

|

|

Realize

an operation integration with the plural number of packer

Thanks to the character of the Arm-shaped Robot System,

the plural number of Packer can be integrated among robot arm motion

range. The usual robot operation cycle of 500 per hour is almost

double capacity as compare to former Bag Placer. ( Robot's maximum

target cycle is 800 per hour.) Furthermore, more than 2 number of

packer that has low packing rate can be integrated by single Robot

Bag Placer. That can realize economical investment for powder packing

system.

|

|

|

|

Automatic rejection

for the bag which not to be inserted into packer filling nozzle

Although the ordinary type of AMO Bag Placer can not

be applied to automatic recovery mode after some kind of bag insertion

incompletion, " RBT-BP Series '' overcomes the said theme and

carry a series of the rejected bag to the appointed position.Thus,

the said sequence operation becomes reality without stopping the

Powder Packing System.

User-friendly Operation Features

Originally, It is said that a series of the industrial

Robot System demonstrates complicated handling motions.On the other

hand, the AMO Robot Bag Placer provides user-friendly operation system

to a series of powder packing industry. A veriety of bag exchange

become effective by using of control panel easily and speedy. In

case of a series of breakdown happening, a portion that containing

failures are displayed in touch screen and helps acknowledge by an

operator and quick recovery. |

|

Apply Robotics Mechanism

to the Side Valve Vynyl Sack

Although the AMO existing packing system can not be applied

to automatic bag placing , bag tumbling down and transportation on

belt conveyor using of Side Valve Vinyl Bag, AMO has newly developed

bag tumbling guides and has achieved complete automation. As the

side valve vinyl bag made from resin treatment film and it is difficult

for the said bag to stacking on the orthodox shaped bag magazine,

AMO applies sideways bag piling-up method using of a tray to the

said bag. As to empty tray replacement, AMO applies loop-shaped automatic

tray conveying system.

|

|

The other Technical Features |

|